Aiko New Hand V2 from 3d printer

2 posters

Page 1 of 1

Aiko New Hand V2 from 3d printer

Aiko New Hand V2 from 3d printer

Hi,

Took me many hours of non-sleep to finish the most natural movement robotic hand.

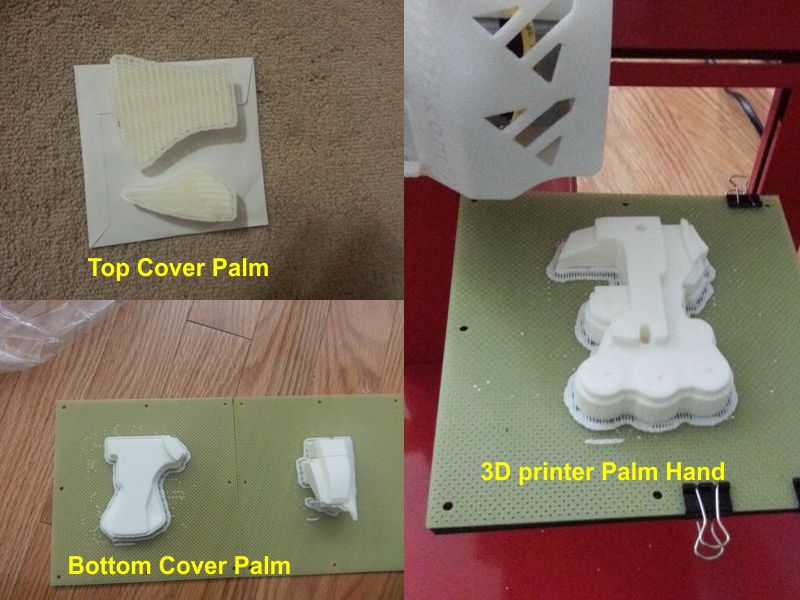

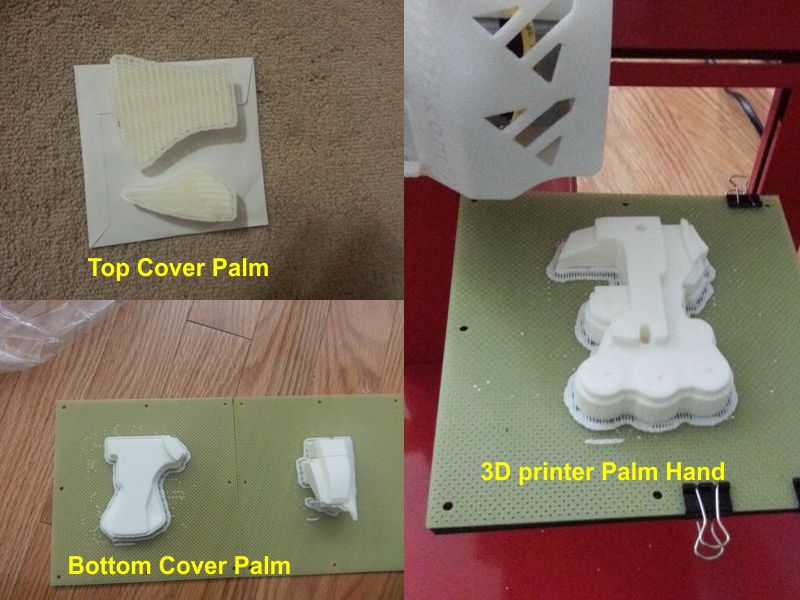

Designed and print from 3d printers.

It takes about 3 hours to print one finger, the hand took about 3 days to print.

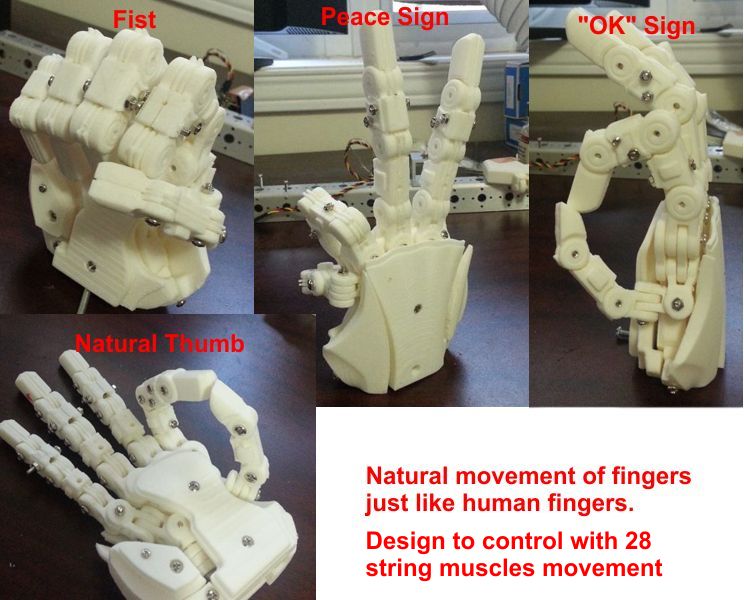

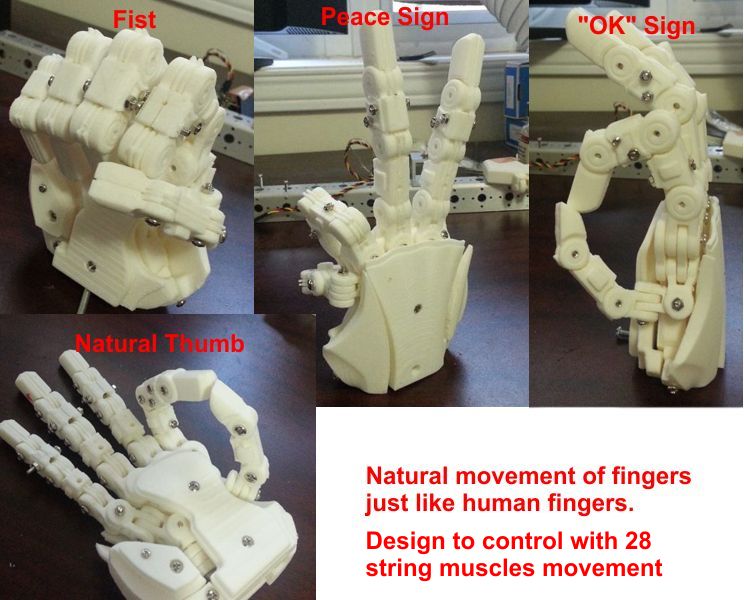

The finger can do abduction, adduction, flex and extention.

Even the palm can move too.

Pinky and thumb movement is almost like human.

From posing peace sign, "OK sign" and even make a fist too.

The thumb can touch all fingers.

Weight about 500g.

Designed to work with 28 Flexinol Wire muscles (try with flexionl wire... work OK)

or

14 servo

I probably going to try both to see which is better.

Took me many hours of non-sleep to finish the most natural movement robotic hand.

Designed and print from 3d printers.

It takes about 3 hours to print one finger, the hand took about 3 days to print.

The finger can do abduction, adduction, flex and extention.

Even the palm can move too.

Pinky and thumb movement is almost like human.

From posing peace sign, "OK sign" and even make a fist too.

The thumb can touch all fingers.

Weight about 500g.

Designed to work with 28 Flexinol Wire muscles (try with flexionl wire... work OK)

or

14 servo

I probably going to try both to see which is better.

3D Printing

3D Printing

Hi everyone,

It has been a long time since I last logged in 2011 and a lot has happen to me, one of which I had a heart attack in 2011 and double by pass heart surgery in Feb 2015. Since the surgery I can only sit around and not do much for a while till things heal, so I have had time to reseach about building things like 3D printers and robots.

There are many video's on youtube now on how to make homemade 3D printers, plus over the last few years I have been collecting old printers for parts.

I also found a guy this year who is 3D printing all his robotic parts and has made them open source. Of course you still have to purchase servo and stepper motors and other stuff but it gives anyone with a 3D print a place to start learning. Now this is not meant to replace Aiko but as a way to develop the inner frame work.

Who knows maybe in the future we will be able to change robotic body parts as easy as changing cell phone covers by 3D printing them out.

InMoov web site http://www.inmoov.fr/shoulder-and-torso/

My new email address is : kenn@kennsplace.com

It has been a long time since I last logged in 2011 and a lot has happen to me, one of which I had a heart attack in 2011 and double by pass heart surgery in Feb 2015. Since the surgery I can only sit around and not do much for a while till things heal, so I have had time to reseach about building things like 3D printers and robots.

There are many video's on youtube now on how to make homemade 3D printers, plus over the last few years I have been collecting old printers for parts.

I also found a guy this year who is 3D printing all his robotic parts and has made them open source. Of course you still have to purchase servo and stepper motors and other stuff but it gives anyone with a 3D print a place to start learning. Now this is not meant to replace Aiko but as a way to develop the inner frame work.

Who knows maybe in the future we will be able to change robotic body parts as easy as changing cell phone covers by 3D printing them out.

InMoov web site http://www.inmoov.fr/shoulder-and-torso/

My new email address is : kenn@kennsplace.com

Poor Man's 3D Printer

Poor Man's 3D Printer

I found this link on how to make a poor man's 3D Printer for under $100 on Instructable.

Poor Man's 3D Printer : http://www.instructables.com/id/Poor-Mans-3D-Printer/

or

You can make one from scratch.

plus you can make your own filament hot end.

and

recycling failed prints to create DIY filament.

You can make your own plastic recycler all though this one is a little over kill,

but it would probably make a good mini mold press machine.

Poor Man's 3D Printer : http://www.instructables.com/id/Poor-Mans-3D-Printer/

or

You can make one from scratch.

plus you can make your own filament hot end.

and

recycling failed prints to create DIY filament.

You can make your own plastic recycler all though this one is a little over kill,

but it would probably make a good mini mold press machine.

Similar topics

Similar topics» Aiko hardware and software BRAINS

» Aiko's small hand video demo

» Want to have your company logo on Aiko! Have Aiko wears the clothes you designed or sale.

» Suggustions for a more realistic appearance

» Aiko Next official public appearance: Nov 6-8 2009

» Aiko's small hand video demo

» Want to have your company logo on Aiko! Have Aiko wears the clothes you designed or sale.

» Suggustions for a more realistic appearance

» Aiko Next official public appearance: Nov 6-8 2009

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|

» introducing the cyberpunk software design pattern

» LG book updates

» LivinGrimoire swift version added

» the living grimoire is now available in python as well

» livingrimoire auxiliary modules

» [Python] Thinkable class

» owly check this out

» the living grimoire AGI